From China’s income situation difficult to see Chinese private enterprises, including ours plastic injection molding industry,The U.S. has 70% of the injection molding industry to move back, and if China plastic mold injection molding industry to continue to survive, to break the monopoly of state-owned enterprises is inevitable.

Chinese household financial investigation and Research Center data show that “the financial industry, utilities, real estate is the highest level of annual wage income of three industries, other industries typically 1.9 to 2.6 times.” Investigation of the center come from different ownership enterprises wages of view, state-owned enterprises, the average wage level of 54,000, only 29,000 private enterprises, state-owned enterprises is the private sector average wage level is about 1.9 times. The average wage income of foreign companies is as high as 86,000.

“State-owned monopoly industries due to hold the telecommunications, electricity, energy, high-value resources, it was easier profitable addition to pay state taxes, as well as considerable profit retention by allowing for the issuance of employee benefits or develop shopping malls, resorts, hotels and other sideline; The relative crowding together in the competitive private manufacturing, consumer goods, foreign trade and other fields. junior staff the income gap between the two conservative estimate of about 2 times. “Zou Wenjiang said.

Analysis of state-owned enterprises pay system is not difficult to find, in addition to employees of state enterprises fundamental wage income, but also includes wages of hidden income, such as a variety of bonuses, subsidies, insurance, prepaid cards, in-kind and other benefits. Industry insiders estimate that this part of the income of employees of state enterprises accounts for about half of total revenue.

Chinese household financial investigation and research center director, dean of Southwest University of Finance and Economics plow willing to accept new financial reporter in an interview that, according to various sources of income contribution to income inequality perspective, wage income gap is caused by China’s current income uneven distribution of one of the main income gap on the overall contribution rate of 40 percent. Followed by the industrial and commercial income disparities, income up 20% of households with an average income of 22,000 yuan business, the average household income of the lowest 20% Business operating income of only 200 yuan. Typically, the main source of income of low-income households or agricultural production, 20% of the lowest-income households, accounting for nearly 50% of agricultural income, wage income and business income accounted for only 13% and 5%. This reflects the current low rate of return of agricultural production reality.

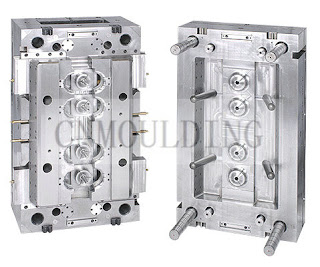

Our website, you will see what is the real Chinese competitors, the responsible plastic injection molding maker -Fair competition in a non-potent weed